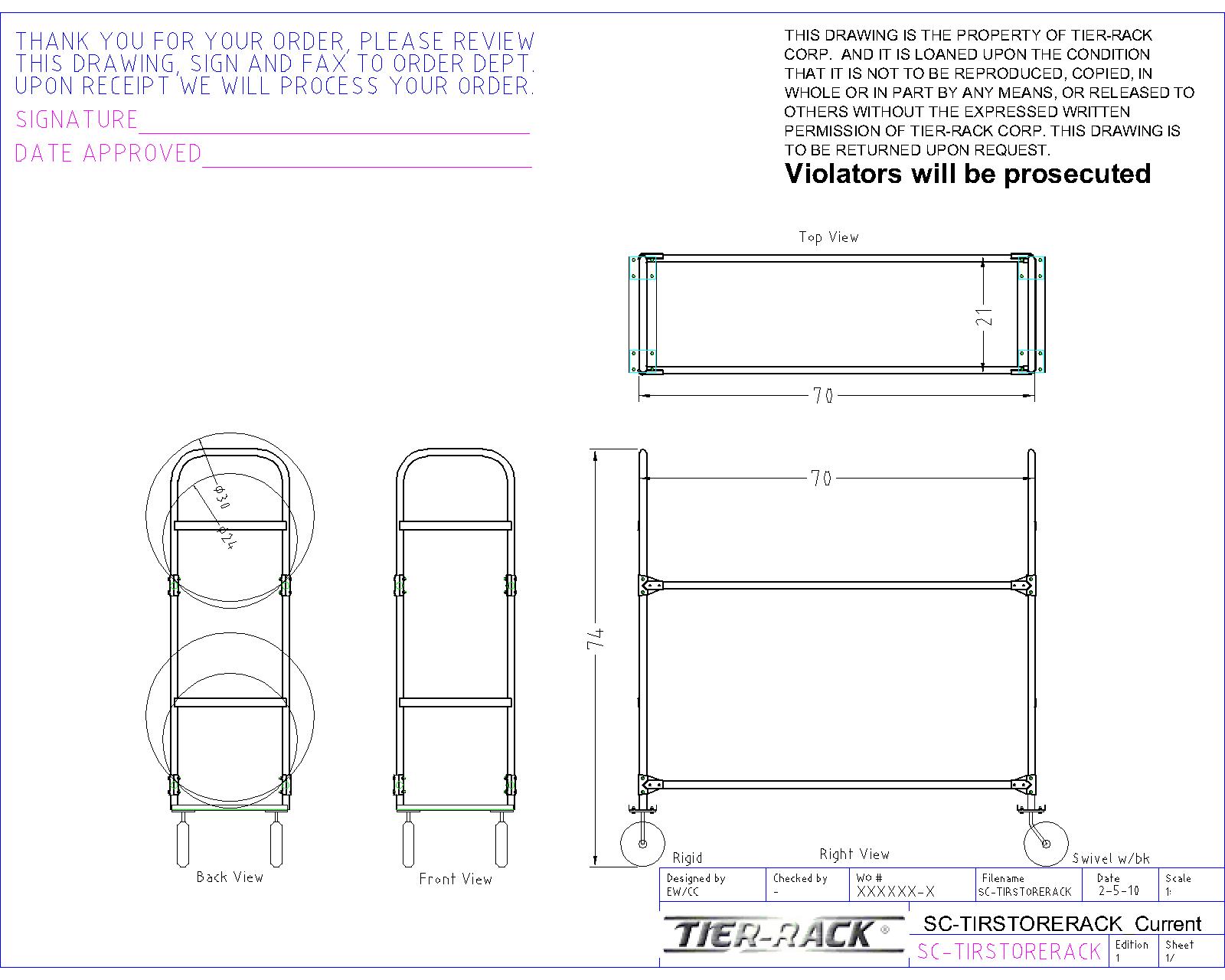

In almost any manufacturing process, production is as fast as the delivery time on the slowest component. Tier-Rack is no different. Our lead time and delivery schedule for stack racks is dependent upon delivery of parts, steel, decking components, paint and other materials required for assembly. For carts, automotive racks or shipping racks, specialized parts or dunnage components may also be required.

Tubular steel is often the last arriving component. Most producing tube mills operate with rolling cycles that may vary from two or three weeks to perhaps six or eight weeks depending on the size and demand for a given size of shipping rack. Mill rolling dates are scheduled in advance since the mill must 1st secure flat rolled coils in the proper gauges and then slit and reroll them to conforming feeder coils to serve the tube production.

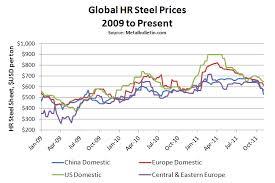

Our purchasing department at Tier-Rack works with multiple tube mills in our supply chain. We visit the key producing mills and invite them into our plants. This is done to gain a full understanding of their capacity and of our production needs. Steel pricing is volatile and can vary widely during a calendar year. At any given time, prices can vary by region, for example Great Lakes vs. Southeast.

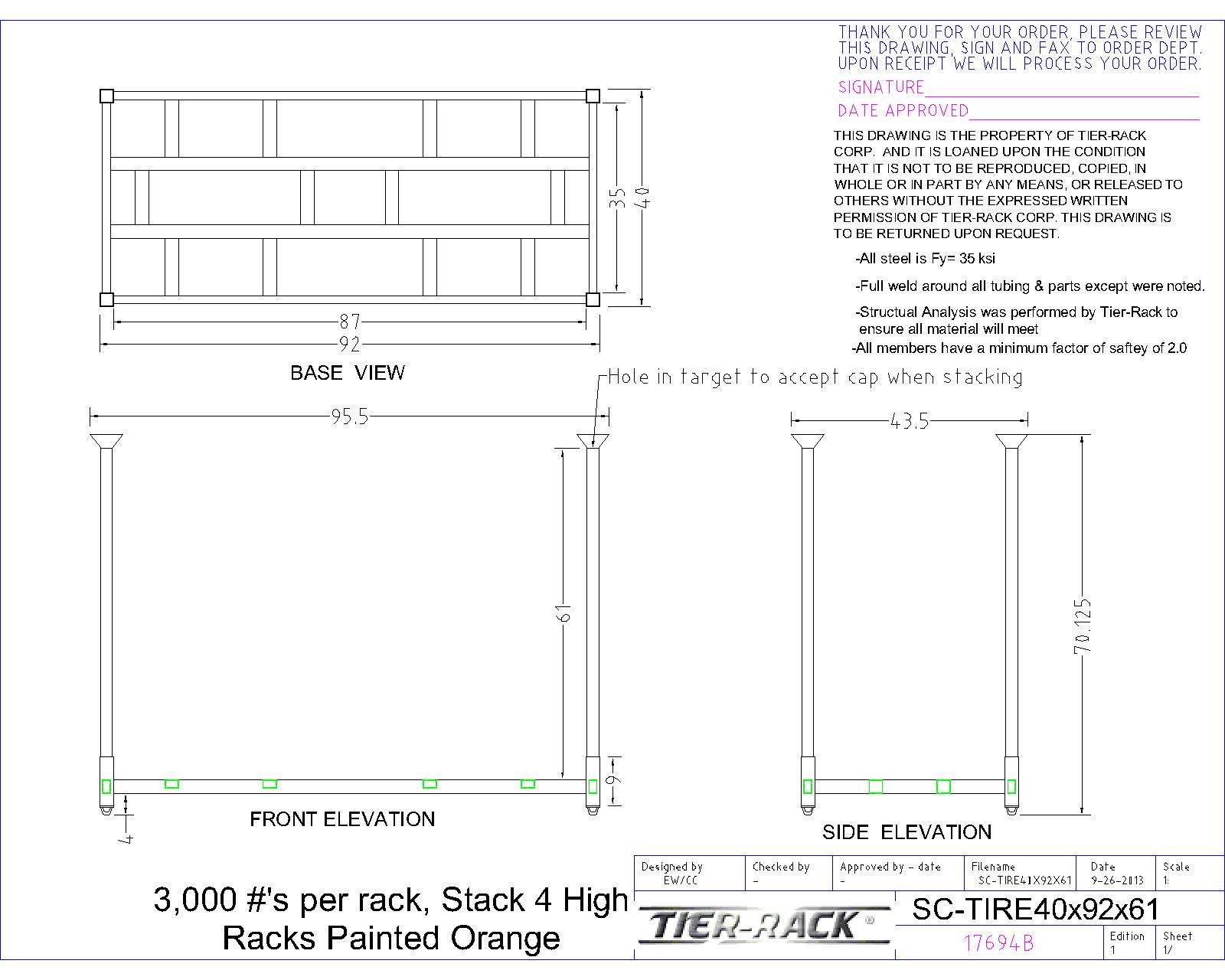

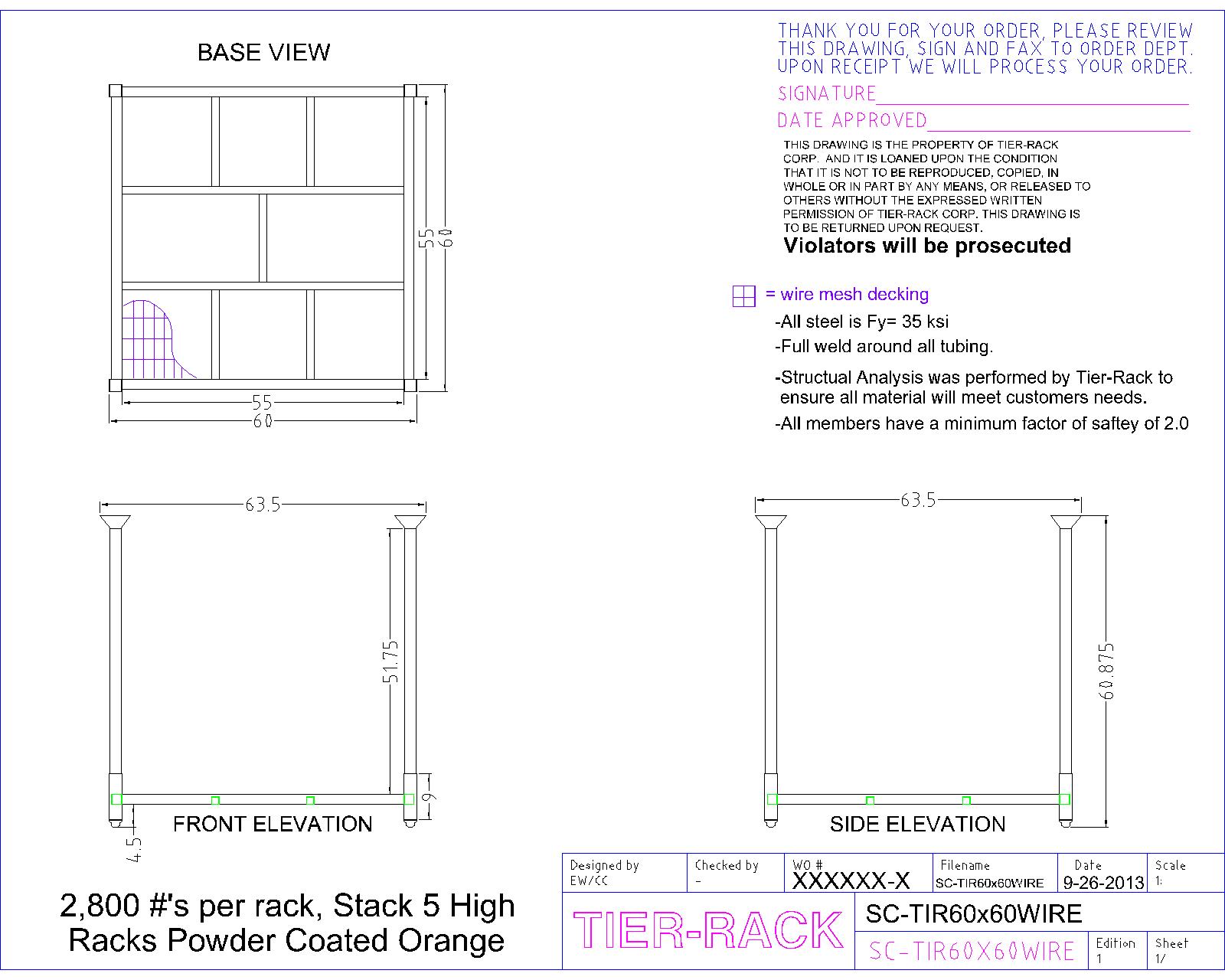

Common mill stocking sizes for tubular steel are 240” (20 feet) and 288” (24 feet). Consider a common post size of 60 ½” – On a 240” length, the waste factor is 24%. On a 288” length the waste factor is almost 20%. Considerable value and cost savings is achieved by ordering a custom mill length of 304”, with near zero cut waste.

On large orders considerable savings are available to our customers who provide a delivery window sufficient to allow for the production cycles on raw materials best suited for the specific job.

.JPG)